Ethanol Storage Area$42 million ETHANOL PLANT (40 MGPY)Penford CorporationCedar Rapids, IA Processing: CJ Schneider Engineering General Contractor : Ambitech Engineering Corporation Concrete Contractor : Weitz Industrial Services Group This facility includes the following area:

Keywords: Industrial, Ethanol, Steel, Concrete, Foundations, Retaining Wall |

|

Index.php

Fermentation Area$42 million ETHANOL PLANT (40 MGPY)Penford CorporationCedar Rapids, IA Processing: CJ Schneider Engineering General Contractor : Ambitech Engineering Corporation Concrete Contractor : Weitz Industrial Services Group This facility includes the following area:

Keywords: Industrial, Ethanol, Steel, Concrete, Foundations, Retaining Wall |

|

PROJECT INFORMATION PAGE |

|

PROJECT PROJECT TYPE: PROJECT METHOD |

NYLEN RESIDENCE

FORENSIC ENGINEERING AND RETROFIT INVESTIGATION-INSPECTION-OBSERVATION-REPAIRS |

|

CONTRACTOR: ARCHITECT STRUCTURAL ENGINEER: OWNER: |

Halman Construction, DK Construction

Kramer-Kreski Design Schneider Structural Engineering, Inc. Mark and Mary Ellen Nylen |

| Project Description: Schneider Structural Engineering (SSE) observed the construction of the residence for structural integrity, and provided repairs design for deficient items. SSE served as an expert witness through the course of the successful trial.

Keywords: Residential, Observation, Forensic, Retrofit, Repairs, Expert Witness, Lumber, Wood, Steel, Concrete

Page author: Vadim Makarov, PhD, PE, SE |

PROJECT INFORMATION |

|

PROJECT: CONSTRUCTED COST: PROJECT TYPE: PROJECT METHOD: |

Notre Dame Debartelo Performing Arts Center

$63.6 Million Higher Education DESIGN BID |

|

CONSTRUCTION MANAGEMENT CONTRACTOR: ARCHITECT: OWNER: MASONRY CONTRACTOR: ARCHITECTURAL PRECAST SUPPLIER: PRECAST CONNECTION DESIGNER: |

Turner Construction Company

SCHNEIDER STRUCTURAL ENGINEERING INC. |

| Project Description: Schneider Structural Engineering provided the Structural Engineering for the Exterior Architectural Precast Panel attachments to the main superstructure of the 150,000 square foot building. The Architectural Precast mimics the existing Gothic Architecture of the University of Notre Dame.

Keywords: Architectural, Steel, GFRC Glass Fiber Reinforced Concrete, Observation-Inspection-Investigation.

Web Page Author: Paul M. Douglas P.E., S.E. |

PROJECT INFORMATION PAGE |

|

PROJECT: CONSTRUCTED COST: PROJECT TYPE: PROJECT METHOD: |

MONFORT ALVEY BOX STORAGE

$ 7 Million estimated FOOD PROCESSING FACILITY DESIGN BID |

|

CONTRACTOR: MECHANICAL ENGINEER: STRUCTURAL ENGINEER: OWNER: |

Project Managed for Owner by Dick Greene with Subcontractors

SCHNEIDER STRUCTURAL ENGINEERING INC. |

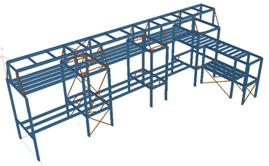

| Project Description: Monfort Inc. is now a subsidiary company of ConAgra Red Meats. SSE has provided engineering services for Monfort Inc. beginning in the early 1990’s at many of their food processing facilities in the country such as Garden City, KS, Greeley, Co., Dumas, TX, and this particular facility in Grand Island, NE. SSE has designed and detailed hot box additions for all the locations listed and has provided the specialized design and detailing of the beamless cooler conveyor systems for the plants in Greeley, CO and Garden City, KS, and Dumas TX for their Sales Cooler Addition. Beamless conveyor systems are unique and sanitary systems that provide structural support of conveyor systems utilizing D.T. saddles, drop rods, and light gauge framing that minimize unsanitary conditions and effects due to condensation issues. In 1997 SSE provided the design and detailing of the Alvey Box Storage addition at the Grand Island, NE facility. At this time box storage systems for meat processing plants were becoming popular to meat processing facilities and were being utilized for increased production of prefabricated meats. The facility in Grand Island was constructed using Insulated metal panel walls and Insulated Precast Concrete Sandwich panel walls surrounding the dock area. The dock area had 2 levels with offices above and the dock area below. The box storage area of this addition also had a mezzanine level constructed with bar grating, structural steel beams, and tube steel columns to support box conveyers that feed into vertical carousel storage elevators that were supported by the structural floor slab. The roof of the addition consisted of bar joists, joist girders, and metal deck.

Web Page Author: Paul M. Douglas P.E., S.E.

|

PROJECT INFORMATION PAGE |

|

PROJECT: CONSTRUCTED COST: PROJECT TYPE: PROJECT METHOD: |

Cargill Box Storage Friona, TX

$ 25 Million estimated FOOD PROCESSING FACILITY DESIGN BUILD |

|

CONTRACTOR: STRUCTURAL ENGINEER: OWNER: |

Mid-Tec Inc.

SCHNEIDER STRUCTURAL ENGINEERING INC. |

| Project Description:

|

Page Author: Paul M. Douglas, PE, SE |

PROJECT INFORMATION PAGE |

|

PROJECT PROJECT TYPE: PROJECT METHOD |

MICHAEL FOODSEXISTING MEZZANINES LOAD RATING, HOISTS LOAD RATING, FALL PROTECTION DESIGN LOAD RATING OBSERVATION-INVESTIGATION-ANALYSIS |

|

STRUCTURAL ENGINEER: OWNER: |

Schneider Structural Engineering, Inc. |

| Project Description: Schneider Structural Engineering (SSE) observed existing Mezzanines, Hoists, gathered information, and furnished structural analysis to come up with the Load Ratings. SSE designed Fall Protection.

Keywords: Steel, Masonry, Wood, Industrial, Food Processing, Load Rating, Fall Protection

Page author: Vadim Makarov, PhD, PE, SE |

| The Greeley, CO Specialty Cooler Addition

The Greeley, CO Specialty Cooler was the last of four additions to be constructed. This addition was unique because it was constructed with 10′-0″ wide precast members with D.T. stems at 5′-0″ o.c.. This required the rail support system components to be designed to support larger loads. Monforts Vice President of Engineering: Don Determann Monforts Project Manager: Dick Greene Engineer of Record : Schneider Structural Engineering Plumbing Engineer : Midlands Mechanical, Inc. Refrigeration Engineer: Preston Refrigeration Co. $200 Million Specialty CoolerAdditions constructed over a 2 year period under the name of Monfort Inc. and consisted of 4 separate Additions in the USA. The facilities in 2002 were owned by Swift and Company which is a Subsidiary of ConAgra and an investor group led by Hicks, Muse, Tate & Furst, Inc. Schneider Structural Engineering was very proud to have been chosen as the Engineer of Record for the 4 separate additions in 4 separate States in the USA. All 4 additions were Fast Track Projects and each was unique in their own way. The Specialty Cooler Additions are also known as “Hot Boxes”. Hot Boxes in the meat processing industry are specialized coolers in which the freshly slaughtered cattle are transported from the kill floor area via rail systems. Inside the Hot Boxes the carcasses are supported by a unique beamless cooler rail system which was previously invented by Schneider Structural Engineering. The beamless cooler rail system utilizes light gauge structural elements to support and brace the rails. The Hot Boxes are specially designed to chill the carcasses quickly without condensation and shrinkage of the meat. The Monfort Hot Box Additions were at the following locations:

Keywords: Architectural, CMU-Concrete Block, Cast-in-Place Concrete, Component Design, Concrete, Construction Administration, Design Bid, Food Processing, Foundations, Industrial, Insulated Metal Panels, Masonry,Observation-Inspection-Investigation, Pile Foundations, Prestressed/Prestressed Concrete, Retaining Wall, and Steel.

|

Web Page Author: Paul M. Douglas P.E., S.E.

|

| The Garden City, KS Specialty Cooler Addition

The Garden City, KS Specialty Cooler was the third of four additions to be constructed. This addition was unique because it was constructed on grade beams and pile caps that were supported by Augercast Piles. Monforts Vice President of Engineering: Don Determann Monforts Project Manager: Dick Greene Engineer of Record : Schneider Structural Engineering Plumbing Engineer : Midlands Mechanical, Inc. Refrigeration Engineer: Preston Refrigeration Co. $200 Million Specialty CoolerAdditions constructed over a 2 year period under the name of Monfort Inc. and consisted of 4 separate Additions in the USA. The facilities in 2002 were owned by Swift and Company which is a Subsidiary of ConAgra and an investor group led by Hicks, Muse, Tate & Furst, Inc. Schneider Structural Engineering was very proud to have been chosen as the Engineer of Record for the 4 separate additions in 4 separate States in the USA. All 4 additions were Fast Track Projects and each was unique in their own way. The Specialty Cooler Additions are also known as “Hot Boxes”. Hot Boxes in the meat processing industry are specialized coolers in which the freshly slaughtered cattle are transported from the kill floor area via rail systems. Inside the Hot Boxes the carcasses are supported by a unique beamless cooler rail system which was previously invented by Schneider Structural Engineering. The beamless cooler rail system utilizes light gauge structural elements to support and brace the rails. The Hot Boxes are specially designed to chill the carcasses quickly without condensation and shrinkage of the meat. The Monfort Hot Box Additions were at the following locations:

Keywords: Architectural, CMU-Concrete Block, Cast-in-Place Concrete, Component Design, Concrete, Construction Administration, Design Bid, Food Processing, Foundations, Industrial, Insulated Metal Panels, Masonry,Observation-Inspection-Investigation, Pile Foundations, Prestressed/Prestressed Concrete, Retaining Wall, and Steel.

|

Web Page Author: Paul M. Douglas P.E., S.E.

|

| The Grand Island, NE Specialty Cooler Addition

The Grand Island, NE Specialty Cooler was the second of four additions to be constructed. This addition was unique because it was constructed on Geopier foundations. Monforts Vice President of Engineering: Don Determann Monforts Project Manager: Dick Greene Engineer of Record : Schneider Structural Engineering Plumbing Engineer : Midlands Mechanical, Inc. Refrigeration Engineer: Preston Refrigeration Co. $200 Million Specialty CoolerAdditions constructed over a 2 year period under the name of Monfort Inc. and consisted of 4 separate Additions in the USA. The facilities in 2002 were owned by Swift and Company which is a Subsidiary of ConAgra and an investor group led by Hicks, Muse, Tate & Furst, Inc. Schneider Structural Engineering was very proud to have been chosen as the Engineer of Record for the 4 separate additions in 4 separate States in the USA. All 4 additions were Fast Track Projects and each was unique in their own way. The Specialty Cooler Additions are also known as “Hot Boxes”. Hot Boxes in the meat processing industry are specialized coolers in which the freshly slaughtered cattle are transported from the kill floor area via rail systems. Inside the Hot Boxes the carcasses are supported by a unique beamless cooler rail system which was previously invented by Schneider Structural Engineering. The beamless cooler rail system utilizes light gauge structural elements to support and brace the rails. The Hot Boxes are specially designed to chill the carcasses quickly without condensation and shrinkage of the meat. The Monfort Hot Box Additions were at the following locations:

Keywords: Architectural, CMU-Concrete Block, Cast-in-Place Concrete, Component Design, Concrete, Construction Administration, Design Bid, Food Processing, Foundations, Industrial, Insulated Metal Panels, Masonry,Observation-Inspection-Investigation, Pile Foundations, Prestressed/Prestressed Concrete, Retaining Wall, and Steel.

|

Web Page Author: Paul M. Douglas P.E., S.E.

|